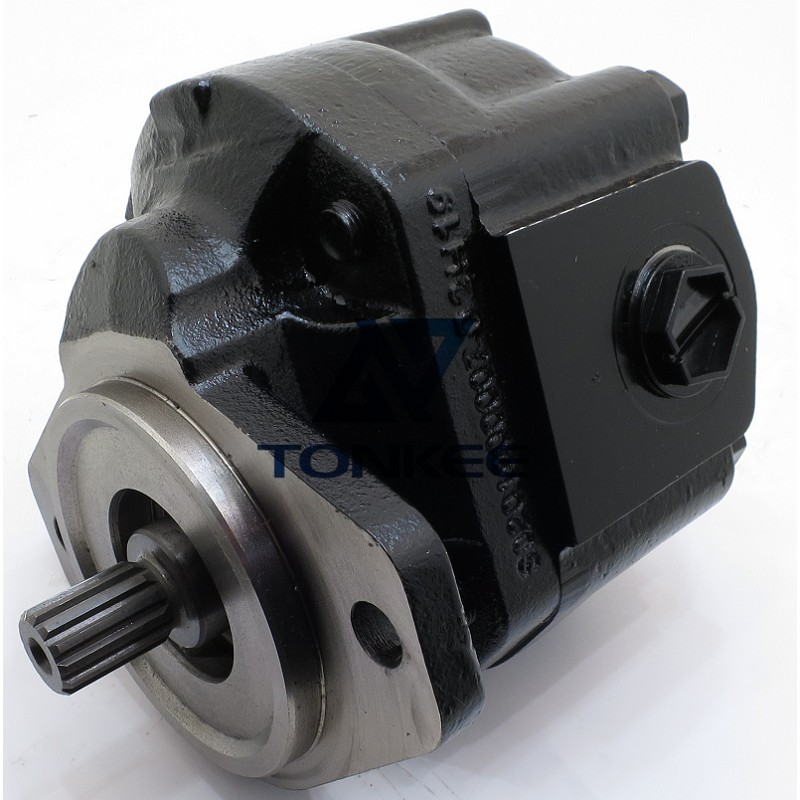

The 5H1-40129TER is a positive displacement hydraulic gear pump, characterized by its ability to move a fixed volume of hydraulic fluid with each revolution.

It is meticulously crafted and engineered to ensure durability and reliability in demanding industrial applications.

Flow Rate:

This hydraulic gear pump is renowned for its impressive flow rate, capable of delivering a substantial volume of hydraulic fluid per unit of time. The specific flow rate varies based on the pump's size and configuration.

Pressure Rating:

The 5H1-40129TER is designed to handle a wide range of hydraulic pressures, making it adaptable to different systems and operational requirements. Its pressure rating is typically specified in pounds per square inch (psi).

Material:

The pump's construction typically employs high-quality materials such as cast iron or steel, enhancing its strength and longevity. These materials are also chosen for their resistance to corrosion and wear.

Mounting Options:

This hydraulic gear pump offers versatility in installation, with options including flange, foot, or bracket mounts. This flexibility allows engineers to design hydraulic systems that meet specific needs and space constraints.

Direction of Rotation:

Hydraulic gear pumps are available in both clockwise and counterclockwise rotation options. The direction of rotation is a crucial consideration when integrating the pump into a hydraulic system.

Sealing and Leakage Prevention:

The 5H1-40129TER incorporates advanced sealing technology to minimize the risk of hydraulic fluid leakage, ensuring efficient and reliable system operation.

Temperature Tolerance:

The pump is engineered to operate within a defined temperature range, ensuring it can function effectively in various environmental conditions without issues related to overheating or freezing.

Noise and Vibration Levels:

Noise and vibration can be problematic in hydraulic systems. This pump is designed with features to reduce noise and vibration, promoting quieter and smoother operation.

Maintenance:

Routine maintenance is essential to ensure the pump's longevity and efficiency. Maintenance tasks typically involve inspecting and replacing seals, monitoring gear wear, and ensuring proper fluid levels and cleanliness.

Compatibility:

Compatibility with other hydraulic components, such as valves, cylinders, and hoses, is a critical consideration when selecting a hydraulic gear pump. Proper compatibility ensures efficient and reliable system performance.