Flow Rate: Hydraulic gear pumps are available in various sizes and flow capacities, typically measured in gallons per minute (GPM) or liters per minute (LPM).

The specific flow rate would depend on the pump's design and intended application.

Pressure Rating: Hydraulic systems often require pumps capable of handling high pressures. The pressure rating of a gear pump determines the maximum pressure it can operate under without failure. These ratings can vary significantly between different models.

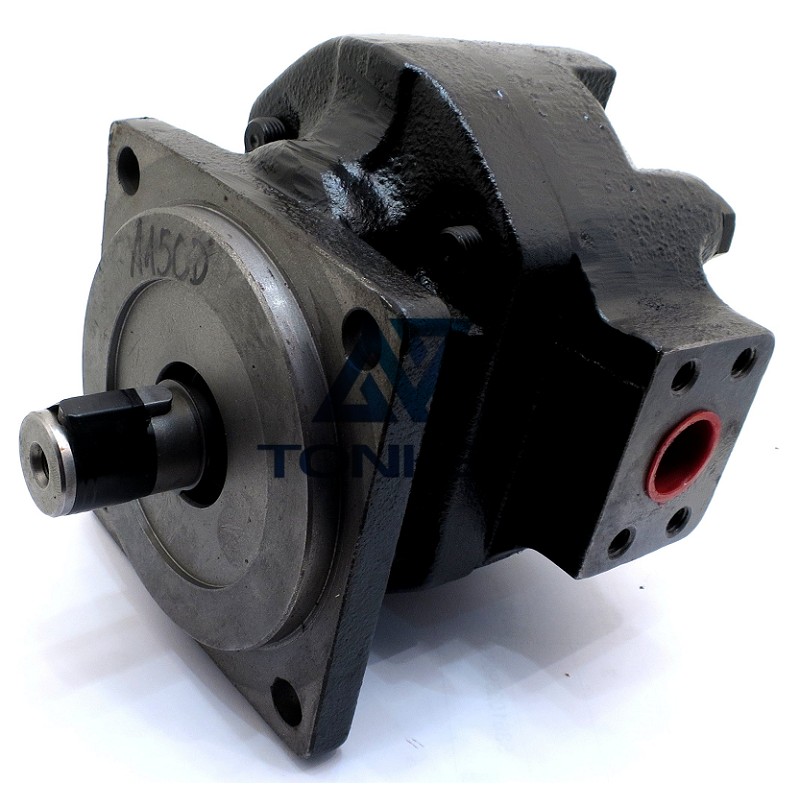

Material and Durability: Hydraulic gear pumps are commonly constructed from materials like cast iron, aluminum, or steel. The choice of material impacts the pump's durability and resistance to corrosion, which is crucial for a long service life.

Mounting Options: Gear pumps can be configured for various mounting options, including flange-mounted, foot-mounted, or shaft-mounted designs. The choice of mounting style depends on the specific requirements of the hydraulic system.

Efficiency and Performance: Hydraulic gear pumps are known for their mechanical efficiency, typically ranging from 80% to 95%.

This means they convert a high percentage of input power into hydraulic output power. The precise efficiency can vary based on design and operating conditions.

Temperature Range: Gear pumps are designed to operate within specific temperature ranges, ensuring they function effectively in both extreme cold and hot environments. Temperature considerations are essential for hydraulic systems used in various industries.

Noise Levels: Gear pumps can generate noise during operation. Noise levels may vary depending on factors such as design, size, and operating conditions. Noise reduction measures may be necessary in some applications.